Hospital bedpan and sluice sinks

EC Combination bedpan sluice sink with flush valve

Franke Model EC Combination Bedpan and Wash-Up sluice sink manufactured from grade 304 (18/10) stainless steel 1.6mm (draining board) and 1, 2 mm thick (bowls)). The combination bedpan and wash-up sluice sink unit have a 150 mm high integral splashback to the rear and 15 mm deep hospital bead 100 mm apron to front and sides.

The hospital sluice sink unit comes with two pressed seamless bowls. The sluice bowl comes with an integral flushing rim and a 38 mm diameter inlet pipe for the flush valve.

The waste outlet on sluice bowl is a 110 mm and the rinse bowl size 610 x 460 x 230 mm deep with a 40 mm waste discharging into sluice bowl. Vermin proof bitumastic sound deadening material covers the underside of the combination bedpan. A galvanized mild steel backing sheet comes standard under the unit.

The combination bedpan comes with:

- Factory fitted Cobra FM 1.00 flush valve

- 35 mm water supply through 50 mm sleeve on unit

- P171/041 pillar mixer with over-arm swivel spout

- CP297 pillar mixer with retractable hand spray

- 15 mm bedpan spray nozzle

- 15 mm bottle spray nozzle (both nozzles activated by two 15 mm quarter-turn elbow action valves).

- Please see below for fixing options.

EC combination bedpan sluice sink with High-Level Cistern

Franke Model EC Combination Bedpan and Wash-Up Sink manufactured from grade 304 (18/10 stainless steel 1.6mm (draining board) and 1,2 mm thick (bowls). Unit with a 150 mm high integral splashback to the rear and 15 mm deep hospital bead 100 mm apron to front and sides. The hospital sluice sink with high-level cistern comes with two pressed seamless bowls. The sluice bowl comes with an integral flushing rim and a 38 mm diameter inlet pipe for the flush valve. The waste outlet on sluice bowl is a 110 mm and the rinse bowl size 610 x 460 x 230mm deep with a 40mm waste discharging into sluice bowl. The underside sprayed with vermin proof bitumastic sound deadening and has a galvanized mild steel backing sheet.

The high-level cistern consists of:

- 11 liters stainless steel high-level cistern

- Ball Flush mechanism and pull chain

- 41mm diameter stainless steel flush pipe and

- 41/38mm reducing chrome plated compression coupling between flush pipe and EC base unit.

EL bedpan sluice sink

Two other options are available. EL bedpan sluice sink with a flush valve which is suitable for areas with normal municipal high-pressure water and the EL bedpan sluice sink with high-level cistern which is used in areas with low-pressure water or intermittent water supply. We recommend using a high-level system in rural areas. The EL bedpan sluice sink is made from grade 304 stainless steel.

EL bedpan sluice sink with flush valve

Franke Model EL Sluice Sink manufactured from grade 304 (18/10) stainless steel 1.6 mm (draining board) and 1,2 mm thick (bowls). Unit with a 150 mm high integral splashback to the rear and 15mm deep hospital bead 100mm apron to front and sides. The unit comes with a pressed seamless sluice bowl with an integral flushing rim and a 38mm diameter inlet pipe for the flush valve. The waste outlet is 110mm. The underside sprayed with vermin proof bitumastic sound deadening and has a galvanised mild steel backing sheet. Unit supplied complete with factory fitted Cobra FMI.00 flush valve, 35mm water supply through 50mm sleeve on the unit, 15mm bedpan spray nozzle, 15mm bottle spray nozzle (both nozzles activated by two 15mm quarter-turn elbow action valves). Please refer to fixing table for fixing options.

EL bedpan sluice sink with high-level cistern

Franke Model EL Sluice Sink manufactured from grade 304 (18/10 stainless steel 1.6mm (draining board) and 1,2mm thick (bowls). Unit with a 150mm high integral splashback to the rear and 15mm deep hospital bead 100mm apron to front and sides. The high-level cistern unit comes with a pressed seamless sluice bowl with an integral flushing rim and a 38mm diameter inlet pipe for the flush valve. The waste outlet is 110mm. The underside sprayed with vermin proof bitumastic sound deadening and has a galvanised mild steel backing sheet.

The high-level cistern consists of:

- 11 litres stainless steel high-level cistern

- Supa Flush Valve and pull chain

- 41mm diameter stainless steel flush pipe and

- 41/38mm reducing chrome plated coupling.

Feet options for EL & EC bedpan sluice sinks

There are four variations for fixing the EC combination bedpan and wash-up sluice sink to the floor. Each system has its own application and advantages.

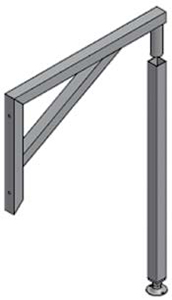

- Gallows brackets with front legs. All made from stainless steel. Gallows brackets are attached to a solid brick wall so that the whole EC combination bedpan cannot be moved. The gallows bracket makes the unit more secure and is much easier to clean under the sink than with four legs.

- Cantilever brackets. The most hygienic method. Used when the underside of the sink must be cleaned easily. This method of fixing cannot be used against drywalls. Cantilever brackets are made from grade 304 stainless steel.

Please note. units longer than 2400 mm require an additional set of legs in the middle for proper support.

EL and EC bedpan sluice sink fixing options. The feet are made from grade 304 stainless steel. The round legs are standard and are included in the price of the EL and EC bedpans. Please specify that you want other legs so that we can quote. Cantilever brackets are often used in hospitals where the cornice is round and feet are not allowed to be placed on the floor for hygiene purposes.