Stainless steel slop hoppers

Sluice sink combination with high level cistern

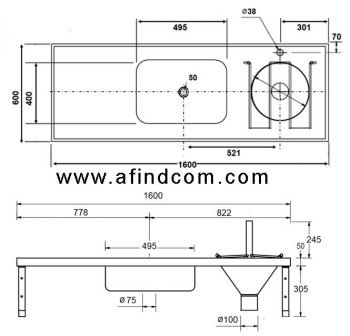

Model SS-AR16L-HLC sluice and sink combo, size 1600x600mm manufactured in 1,2mm thick grade 304 (18/10) stainless steel with one sink bowl size 495x400x190mm with provision for a 40mm waste outlet and a sluice with hinge bucket grid fitted over the funnel adjacent to sink bowl. The sluice bowl is fitted with an integral flushing rim and a 38mm round x 150mm long vertical flush pipe inlet and 100mm outlet. The 100mm outlet is connected to a PVC underground gulley trap (SW-PGT110). The unit has an 50x15mm apron all round. The underside of the draining board is fitted with a mild steel galvanized sheet and supporting frame. Unit to be fitted with 40mm square stainless steel gallows brackets to back and 40mm round stainless steel legs with adjustable foot pieces to the front.

Features:

- 11 liters stainless steel high level cistern with 1450mm stainless steel flush pipe and chrome plated coupling which is reduced on one end to fit the 38 mm connection.

- Trigger spray GR-27512000 fits in a lead through GR-27151000

- Cobra 128-15/NV DZR brass stop tap which activates the trigger spray and installed above the splashback behind the trigger spray

- CO-171/041/N deck mounted kitchen sink mixer is installed behind the bowl

SHBC-OLSB-R Slop hopper basin combo on one level

The SHBC is a slop hopper basin combo all in one level. It can be ordered with either a flush valve (WC-106T or WC-104T) or with a high level cistern. The splashback is also optional. The main bowl can be customized. Standard length for the SHBC is 1600mm but the length can be customized. Note the shortest length is 1200mm.

Tap holes can be pre-drilled to the back or sides of the main center bowl.

SS-SH single slop hopper

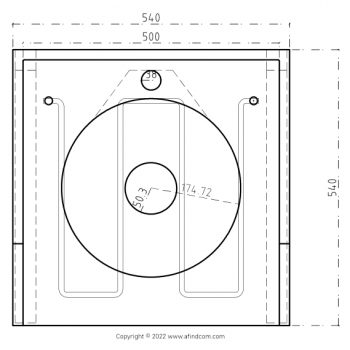

Model SS-SH Slop Hopper 540 x 540 mm manufactured from grade 304 (18/10) stainless steel 1,2 mm thick with a 100 mm high integral splash back to the rear and both sides. The cone has an integral flushing rim and a 110 mm waste outlet for pan connector, the inlet is fitted with a 38 x 250 mm long vertical flush pipe for a standard top entry flush valve, such as the W-106. A hinged bucket grid, manufactured from 10 mm diameter grade 304 (18/10) stainless steel round bar is fixed over the hopper opening. The slop hopper is wall mounted with two 40 x 40 mm square stainless steel wall mounting gallows brackets. Unit fixed to wall 600 mm from the top of the front apron to the finish floor level with 4 off anchor bolts (bolts not supplied). Note plumbing or flush valve is not included in the price of the SH slop hopper.

SS-SH-1000 single slop hopper

Model SS-SH-1000 Slop Hopper 1000 x 540 mm manufactured from grade 304 (18/10) stainless steel 1,2 mm thick with a 100 mm high integral splash back to the rear and both sides. The cone has an integral flushing rim and a 110 mm waste outlet for pan connector, the inlet is fitted with a 38 x 250 mm long vertical flush pipe for a standard top entry flush valve, such as the W-106 or high level cistern. A hinged bucket grid, manufactured from 10 mm diameter grade 304 (18/10) stainless steel round bar is fixed over the hopper opening. The sluice section can either be to the left or the right. The slop hopper is wall mounted with two 40 x 40 mm square stainless steel wall mounting gallows brackets. Unit fixed to wall 600 mm from the top of the front apron to the finish floor level with 4 off anchor bolts (bolts not supplied). Note plumbing or flush valve is not included in the price of the SH slop hopper.

Standard Flushing Method Using Flush Valve methods:

Walcro 104T Flush valve – 35 mm water supply flush valve. Comes with isolating check valve and telescopic adjustment and top entry flush pipe. The flush valve is made from CP DZR brass and is operated via a small lever on the side of the valve.

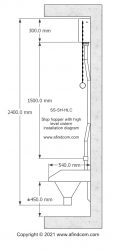

Slop hopper with high level cistern:

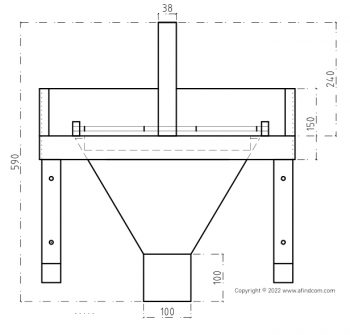

Stainless steel slop hopper (SS-SH-HLC) with a high-level cistern and its components:

- 11 liters stainless steel high-level cistern

- Supa Flush Valve and pull chain

- 41mm diameter stainless steel flush pipe and

- 41/38mm reducing chrome plated coupling.

- Standard stainless steel top entry slop hopper

Use the high-level cistern option with low water pressure or in rural areas. The high-level cistern is easy to maintain compared to a high pressure flush valve which has a complex mechanism. The flush valves require clean filtered water. We do not recommend using borehole water with flush valves, rather install a high level cistern.

Specification: Slop hopper SS-SH-HLC with dimensions 540x540x575mm, manufactured from 1.2mm thick grade 304(18/10) stainless steel. A 100mm high integrated splashback to the left, right and back end. The hopper (cone) is seamless and no prominent signs of welding. The hopper has an integrated flushing rim attached to a 38x250mm vertical flush pipe on which the high level cistern is fitted with a compression adaptor. The hopper outlet is ±101mm in diameter on which a gulley trap connecter is fitted (Not included). The hopper is covered with a swivel hinged bucket grid manufactured from 10mm diameter grade 304(18/10) stainless steel. The slop hopper is mounted against a brick wall with two 40x40mm square stainless steel gallows brackets and four anchor bolts (Not supplied). The unit is installed as low as possible but not higher than 600mm from the top of the front apron to the floor.

CHBC Slop hopper basin combination description

The CHBC slop hopper basin combination (combo unit) is made from 1.2mm thick grade 304 stainless steel. Dimensions: 965 x 550 mm. The CHBC slop hopper basin combo unit saves space inside the hospital since it combines a slop hopper and basin. Furthermore, they are right next to each other making work more efficient and hygienic.

The CHBC Slop Hopper Basin Combo has two flushing options.

CHBC Slop Hopper combination with flush valve

This combination is ideal for most hospitals and clinics. You require a good source of 3 bar water supply in order for the flushing mechanism to work properly. The following Walcro flush valves are recommended:

- Walcro 104T with isolating valve

- Walcro 106T without isolating valve

We recommend the Walcro 104 with isolating valve because it makes maintenance very easy (Note that the Walcro 550 cannot be used in this system). You don’t need to shut off all the water of the floor, you only need to close the isolating valve to work on the flush valve. In areas where water is not that clean and building and alterations persist, we recommend using an inline strainer or filter to reduce maintenance and downtime on the flush valve.

CHBC Slop Hopper combination with stainless steel cistern.

This option is ideal for rural hospitals and clinics. No need to worry about maintaining water pressure, as long as there is enough pressure to fill the stainless steel cistern the unit will work properly. Two types of cisterns are available;

- Low-level cistern with front flush mechanism

- High-level cistern with pull chain.

The most effective option is the high level cistern as the water flushes with higher pressure and velocity.

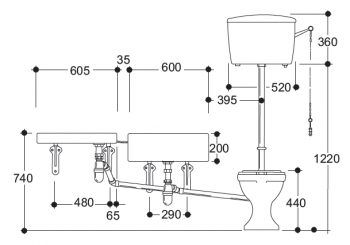

Vaal Ceramic slop hopper combo

The ceramic slop hopper combo is made from high-quality ceramic fireclay. Left hand and right-hand versions are available and are all made on order. It comes as a complete unit and is ready for installation. The ceramic slop hopper combo consists of the following components:

Components

- 104° Outlet slop hopper 405 x 530 x 360 mm, complete with resin pads, c.p. bucket grating, and PVC junction pan connector.

- Fireclay Lab sink 600 x 400 x 200 mm (code 2361). With 38 mm c.p. waste (86 mm flange, 89 mm tailpiece) and plug (code 8783Z0), with PVC bottle trap and waste pipe.

- Drainer 605 x 400 mm (code 1461), with bottle trap and waste pipe.

- 4 x brackets (code 8106Z0).

- 2 x levelling plates (code 8123Z0).

- 2 x outlet levelling plates (code 8124Z0).

- Protea 11 litre high-level cistern complete with fittings and chain (code 7102HL).

- Chrome plated flush pipe and holderbat (code 1710Z2).

Accessories (optional):

- 1 x c.p. 13 mm wall type combined mixer supply fitting with lever handles,

- flexible tube

- jet nozzle and

- wall hook (Cobra code 518-21).

Specifications

- Slophopper 13.50 kg 0.070 m³

- Sink 21.00 kg 0.048 m³

- Drainer 12.50 kg 0.027 m³

- Cistern 23.00 kg 0.050 m³